"The need for efficient and sustainable energy solutions while cutting off carbon emissions continues to grow, as our world sees the negative impact of its lack of consideration for the environment has had."

What if we could save millions of dollars of manufactures along with slashing the carbon emissions to almost it's half. Here's a solution that modern technology has gifted with recent advancements " switched reluctance motor (SRM) ".

Since these past 100 years, the traction motor technologies have progressed from dc motors, induction motors, and lately, to permanent magnet (PM) motors.

Although high-performance PMs provide high efficiency and high torque density, they are unsustainable because of the scarcity of rare-earth materials they rely on.

So besides the need to further reduce CO2 emissions from hybrid vehicles, there is a requirement to eliminate the use of rare earth elements also.

Turntide is a company focused on meeting this need with an electric, smart motor design that has the potential to reduce electricity consumption and carbon emissions by more than 25%.

Ryan Morris, Turntide's executive chairman, said, "What intrigued me at first was that this thing is actually the simplest mechanical electric motor that can be made, but you need electronics and software that are precisely shaping the current that goes into that motor."

As a new speed control system, the SRM drive system is being integrated with power electronic technology, computer control technology, and microelectronics technology.

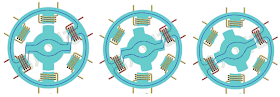

SRMs operate by switching currents in the stator windings in response to changes in the magnetic circuit formed by the rotor and stator. The stator contains windings, but the rotor is simply made of steel that is shaped into salient poles, with no windings or magnets.

There are fewer poles on the rotor than on the stator. When the rotor and stator poles are out of alignment, the magnetic circuit between them has a high reluctance.

The basic principle behind its working is that the magnetic flux has a tendency to flow through the lowest reluctance path, therefore the rotor always tends to align along the minimum reluctance path, which means when stator phase winding A is energized, the rotor aligns along with this phase. As soon as the rotor align along with the A phase, B phase must be energized and A phase must be de-energized if clockwise rotor rotation is required.

Unlike standard induction motors, an SRM has no rotor bars and therefore, no torque-producing current flow in the rotor. Also since they have rotors with no magnets or windings, they have lower inertia and can, therefore, achieve higher accelerations and speeds than PM motors.

Because of its simplified design, and the fewer parts required for it, estimates show that SRMs could cost up to 11% less than standard motors.

Forces from a magnetic field on the rotor's iron can be up to 10 times stronger than those created by current-carrying conductors. This means that these motors could be much more affordable and efficient than standard motors.

It's quite evident now that Turntide's model has the potential to become the world's most efficient electric motor. The company hopes to scale its model globally. Their model can replace motors of all sizes and is applicable in a variety of industries, but Turntide is focusing first on introducing it into buildings and agriculture.

As explained by Morris, "Replacing the motors, just in (U.S.) buildings, would be the carbon equivalent of giving the world a brand new Amazon rainforest."

While SRMs can have very high power density at low cost, they have had issues with high torque ripple when operated at low speed, and the acoustic noise caused by torque ripple.

Now answer this: "Which company has been providing high precision drive systems (motors) to NASA for their Mars rover projects ?"

And do not forget to share this article with others.

Here are the references from where you can learn more about SRMs :

1. https://www.sciencedirect.com/science/article/pii/S2214993715000032

2. https://en.wikipedia.org/wiki/Switched_reluctance_motor

3. https://turntide.com/technology/

What if we could save millions of dollars of manufactures along with slashing the carbon emissions to almost it's half. Here's a solution that modern technology has gifted with recent advancements " switched reluctance motor (SRM) ".

Since these past 100 years, the traction motor technologies have progressed from dc motors, induction motors, and lately, to permanent magnet (PM) motors.

Although high-performance PMs provide high efficiency and high torque density, they are unsustainable because of the scarcity of rare-earth materials they rely on.

So besides the need to further reduce CO2 emissions from hybrid vehicles, there is a requirement to eliminate the use of rare earth elements also.

Turntide is a company focused on meeting this need with an electric, smart motor design that has the potential to reduce electricity consumption and carbon emissions by more than 25%.

Ryan Morris, Turntide's executive chairman, said, "What intrigued me at first was that this thing is actually the simplest mechanical electric motor that can be made, but you need electronics and software that are precisely shaping the current that goes into that motor."

As a new speed control system, the SRM drive system is being integrated with power electronic technology, computer control technology, and microelectronics technology.

Working of a Switched Reluctance Motor (SRM)

SRMs operate by switching currents in the stator windings in response to changes in the magnetic circuit formed by the rotor and stator. The stator contains windings, but the rotor is simply made of steel that is shaped into salient poles, with no windings or magnets.

There are fewer poles on the rotor than on the stator. When the rotor and stator poles are out of alignment, the magnetic circuit between them has a high reluctance.

The basic principle behind its working is that the magnetic flux has a tendency to flow through the lowest reluctance path, therefore the rotor always tends to align along the minimum reluctance path, which means when stator phase winding A is energized, the rotor aligns along with this phase. As soon as the rotor align along with the A phase, B phase must be energized and A phase must be de-energized if clockwise rotor rotation is required.

What makes it more efficient than other motors?

Unlike standard induction motors, an SRM has no rotor bars and therefore, no torque-producing current flow in the rotor. Also since they have rotors with no magnets or windings, they have lower inertia and can, therefore, achieve higher accelerations and speeds than PM motors.

Because of its simplified design, and the fewer parts required for it, estimates show that SRMs could cost up to 11% less than standard motors.

Forces from a magnetic field on the rotor's iron can be up to 10 times stronger than those created by current-carrying conductors. This means that these motors could be much more affordable and efficient than standard motors.

It's quite evident now that Turntide's model has the potential to become the world's most efficient electric motor. The company hopes to scale its model globally. Their model can replace motors of all sizes and is applicable in a variety of industries, but Turntide is focusing first on introducing it into buildings and agriculture.

As explained by Morris, "Replacing the motors, just in (U.S.) buildings, would be the carbon equivalent of giving the world a brand new Amazon rainforest."

While SRMs can have very high power density at low cost, they have had issues with high torque ripple when operated at low speed, and the acoustic noise caused by torque ripple.

Now answer this: "Which company has been providing high precision drive systems (motors) to NASA for their Mars rover projects ?"

Here are the references from where you can learn more about SRMs :

1. https://www.sciencedirect.com/science/article/pii/S2214993715000032

2. https://en.wikipedia.org/wiki/Switched_reluctance_motor

3. https://turntide.com/technology/

Maxom motors

ReplyDeleteTechnology at it's peak.... An astounding article it is....

ReplyDeleteThank You. We hope for your reviews and suggestions ahead as well.

DeleteMaxon Motors.... btw this article is literally boring. Previous one and like that, which light upon technologies rather than their process which indeed bounces upon head, are totally readable and untroublesome. So, best to work upon them.

ReplyDeleteWe will definitely work on them in the upcoming blogs. We hope for your reviews and suggestions ahead as well.

Delete