3D printing technology is already changing the way we produce objects from tools and toys to clothing and even body parts. The 3D printing process builds a three-dimensional object from a Computer-aided design (CAD) model, usually by successively adding material layer by layer, which is why it is also called additive manufacturing. It allows designers to create complex parts for machines, airplanes, and cars at a fraction of the cost and time of standard means like forging, molding and sculpting. As the COVID-19 panic continues to spread across the world, engineers and scientists are working hard developing high tech protective masks, face shield, Venturi valve respirator, hands-free door openers, etc with the use of 3D printing to cope up the shortage.

So, today we will see how 3D printing can change the world of manufacturing, construction, healthcare, etc. But first, we will go through 3 most used 3D printing technologies across the globe.

So, today we will see how 3D printing can change the world of manufacturing, construction, healthcare, etc. But first, we will go through 3 most used 3D printing technologies across the globe.

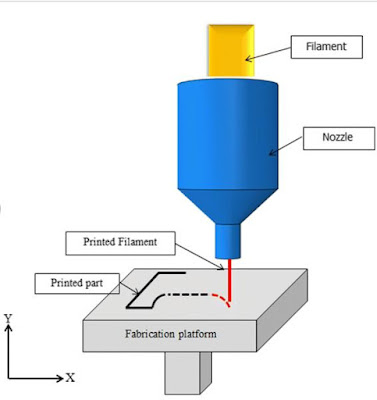

Fused Deposition Modelling (FDM)

It is the most widely used method for 3-D printing (46% in 2018 acc. to Statista). The thermoplastic filament which is a modeling material like acrylonitrile butadiene styrene (ABS), polycarbonate (PC) or polyetherimide (PEI) is present inside an FDM printer is heated to its melting point and then extruded, layer by layer, to create a three-dimensional object. During printing, these materials take the form of plastic threads, or filaments, which are unwound from a coil and fed through an extrusion nozzle. The nozzle melts the filaments and extrudes them on to a base which is controlled by a computer. This technology is used to produce LEGO bricks, whitewater canoes, end-use parts- particularly the small detailed parts specialized in manufacturing tools as well as in food and drug packing.

Selective Laser Sintering (SLS)

It is the second most used 3D technology around the world (38% in 2018 acc. to Statista). It involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic, metal, ceramic, or glass powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed. It is a rapid prototyping technology with a range of applications, including those with snap fits, living hinges, and other mechanical joints.

Stereolithography (SLA)

It comes third on the list of most used 3D printing technologies (33% in 2018 acc. to Statista). SLA Production Printers build accurate parts directly from 3D CAD data without tooling by converting liquid plastic (photopolymer) into solid cross-sections using an ultraviolet laser. The part is created layer by layer, with each resin layer built on top of the next until the part is complete. This process is also known as Photopolymerization. It is particularly used for creating highly precise 3D printed casting patterns from small to very large scale, quickly and inexpensively.

Hope you understood how 3D printing works. Let's take a look at its applications in different sectors but first, we will find how it is being used to tackle the COVID-19 situation.

3D printing for COVID-19

The 3D printed add-on can convert standard equipment that is already available in most hospitals into a non-invasive PEEP mask (NIP) that can be connected to the oxygen supply. This device facilitates breathing for COVID-19 patients and it gives them an extended period of time before mechanical ventilators are required for treatment. Also, to perform COVID-19 tests successfully, nasopharyngeal (NP) swabs needed to collect samples, can be now 3D printed using Digital Light Processing (basically it's like SLA but the light source is replaced with a projector screen which flashes the image of the layer). Engineers are also working to develop a 3D printed ventilator prototype in the wake of the COVID-19 pandemic. Ethereal Machines, a Bengaluru-based start-up, is addressing the problem to some extent by enabling the existing ventilators to cater to the different requirements of multiple patients with the use of 3D printed Splitters. For example, the 30-70 split ratio can be used in cases where one patient is healthy and another's condition is deteriorating. In Spain, Airbus, one of the largest airline manufacturer in the world, has dedicated more than twenty 3D printers to produce visors (face shields) from which more than 100 have already been dispatched.

3D printing in Manufacturing

The manufacturing industry is always looking at new and innovative ways of working and in recent years, 3D printing has been at the forefront. Advancements in the 3D printing technology, equipment and materials have resulted in the costs being driven down, making it a more feasible option to general manufacturing use. If we take a look at this technology in production, IDAM (Industrialization and Digitization of Additive Manufacturing for Automotive Series Processes) project has addressed the lack of standardization in AM processes and material properties and expected to result in 50,000 mass-produced automotive parts and 10,000 spare parts being printed in 2020.

3D printing in Construction

3D printing allows for the creation of products using a quick and cost-effective process. This has opened the gates to new construction methods both on the commercial and consumer side of things, better construction techniques, and even safer construction methods. An Austin-based startup Icon can build a house nearly 200 times faster. The company is building houses that max out at 800 square feet, but that’s not the limit. The hyperspeed fabrication is the work of a mega-size 3D printer named the Vulcan. Engineers run digital blueprints for the home through Slicer software, which translates the design into the programming language G-code. That code determines where the printer moves along its track, extruding 3⁄4-inch-thick layers of concrete-like icing on a cake. The base material—a finely calibrated mix of cement, sand, plasticizers, and other aggregates—gets poured into a hopper at the top of the printer and flows onto the rising walls below.

The printers are large and cumbersome, have a portal design, have limits on the height of the printed building and are not easy to transport and assemble. So, we need to create a low-cost, functional 3D printer that can work in complex operating conditions as it eliminates the cost of workers, tools and processing of raw materials in factories and reduces the time as well.

3D printing in HealthCare

One of the revolutionary inventions in the field of medical science, 3D printing has made it easy and possible to offer customized healthcare solutions. This technology has enabled customizations, prototyping, manufacturing, and research. Instances like bio-printing which can create artificial living tissues can advance medical research. Moreover, patient-specific organ replicas can increase the percentage of successful complicated operations. Not only these, sterile surgical instruments which can be more precise than the conventional ones and prosthetic limbs customized to suit and fit the wearer are the major applications of 3D printing. Dubai has hospitals where the use of 3D printing is mandated liberally and they successfully operated a patient who had a cerebral aneurysm in four arteries using a 3D model of her arteries. In January 2018, a 22 years old patient was successfully practiced for kidney transplants using a 3D model of her donor’s kidneys because her father didn’t match the blood group in Belfast. US-based laboratory and research company Organovo is working on printing liver and intestinal issues for medical research and development drugs for various diseases and in May 2018, they presented their pre-clinical results for the functionality of its living tissue for type I Tyrosinemia. The Wake Forest Institute of North Carolina in May 2018 announced that the organoids they developed using 3D printing have a fully cell-based, functional blood-brain barrier that mimics normal human anatomy. It has also been working on 3D printing skin grafts that can be applied directly to burn victims. And the list is still long. According to the sources, it has been forecast that 3D printing in the medical field will be worth $3.5bn by 2025, compared to $713.3m in 2016. The industry’s compound annual growth rate is supposed to reach 17.7% between 2017 and 2025.

Either it is Manufacturing or Construction or Medical or Consumer goods, 3D printing is not only reserved to prototypes but it has gone far away from that and in the coming years, it will be a lot more than that because even though it has challenges of cost and software setups, it has a lot more advantages to overshadow them replacing the traditional methods.

Thanks for reading. IEEE SB NITP would like to once again remind its readers to obey the guidelines as issued by the Government and WHO. Stay home and stay safe. Please drop your views in the comment section.

Hello, this weekend is good for me, since this time i am reading this enormous informative article here at my home. flux laser cutter

ReplyDeleteHi, This is Noah D. I am a blogger n SEO expert at 3DSculpLab. Nowadays we are working with our official website 3dsculplab.xyz. We need some who can write on our niche.

ReplyDelete3DSculpLab

We just love to give more than our client's expectations, be it in terms of quantity, quality or commitment. And we have been quite successful in that too! Because, within few years we got many projects, one of few are fully fledged e-Commerce websites, ERP, Vendor Management system. And none of these clients came through any advertising our SEO team dedicatedly works for our website ranking on Google search.

ReplyDeleteSoftware developer company

Spwebconnect is a best website development company in pune. We also provide website designing services in Mumbai, Dhule, Nashik, Jalgaon, Nagar, Kolhapur, Goa, etc. We Develop Static as well as Dynamic Mobile Responsive Website, Custom Softwares, Android and iOS applications. We just love to give more than our client's expectations, be it in terms of quantity, quality or commitment. And we have been quite successful in that too! Because, within few years we got many projects, one of few are fully fledged e-Commerce websites, ERP, Vendor Management system. And none of these clients came through any advertising our SEO team dedicatedly works for our website ranking on Google search.

ReplyDeleteWebsite designer company in Pune

Very efficiently written information. It will be beneficial to anybody who utilizes it, including me. Keep up the good work. For sure i will check out more posts. This site seems to get a good amount of visitors. CO2 laser cutter

ReplyDeleteVery efficiently written information. It will be beneficial to anybody who utilizes it, including me. Keep up the good work. For sure i will check out more posts. This site seems to get a good amount of visitors. laser engraving A laser engraving business is a very profitable business one can start from home. For someone thinking of pulling out of formal employment, laser engraving offers a great opportunity to venture into business.

ReplyDeleteFourcreeds

ReplyDeleteFire insurance in India underwent a growth of 28.1% in FY21. Property insurance formed the 3rd largest general insurance market in 2021 and had a 25.4% share of Gross Written Premiums. The figures imply that both kinds of insurance have a high demand in the country. But in what aspects do they differ? Here’s a look.

ReplyDelete